We are committed to developing Carbon Capture and Storage (CCS) as the ultimate solution to achieve our Net Zero ambition by 2050. Some of these initiatives are supported by the European Union (EU) Innovation Fund.

What is Carbon Capture and Storage?

Carbon Capture and Storage (CCS) is a cutting-edge technology designed to capture carbon dioxide (CO₂) emissions produced by industrial processes before they enter the atmosphere. The captured CO₂ is transported to a suitable location, and securely stored. Potential storage methods include injection into underground geological formations, such as depleted oil and gas reservoirs or saline aquifers.

At Cementir Holding, we are committed to sustainability and innovation, and CCS plays a vital role in our journey towards achieving carbon neutrality by 2050.

Our CCS efforts complement innovative initiatives like FUTURECEM®, D-Carb®, and energy-efficient kiln technologies and all other measures to curb emissions, which are detailed on our Sustainability Strategy.

CCS – The ACCSION Project

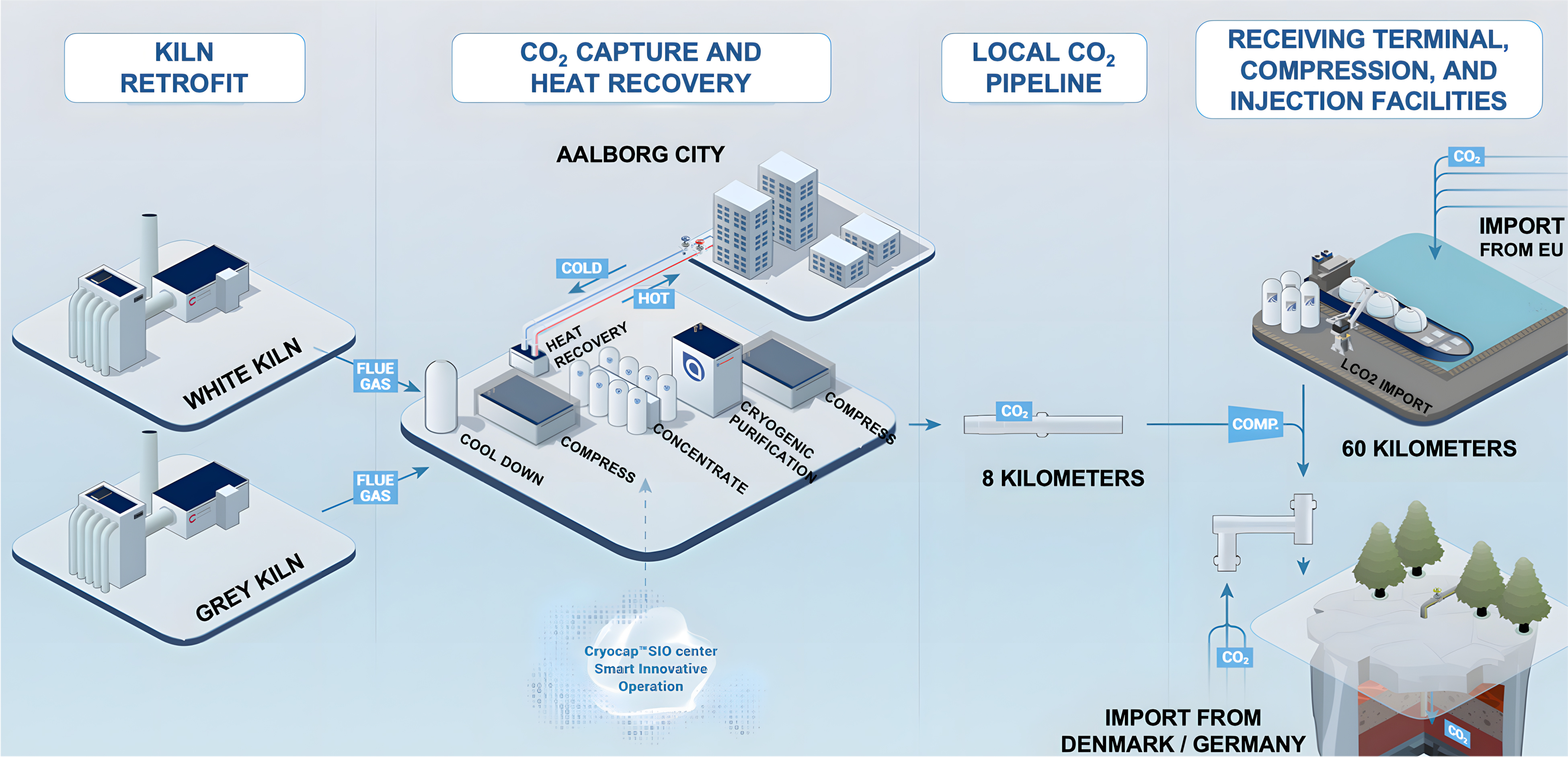

ACCSION stands for Aalborg CCS using Infrastructure Onshore in North Jutland. It is Cementir first carbon capture industrial project and one of the first and largest full onshore carbon capture and storage value chains featuring inland geological storage in Denmark.

- Objective: avoidance of 1.5 million tons CO2 per year at the Aalborg site by 2029.

- Location: Aalborg, Denmark

- Technology: Cryogenic technology (Cryocap™) enabling high-purity CO₂ capture from cement grey and white kiln emissions

- Technology partner: Air Liquide

- Capex subsidy: € 220 million from the EU Innovation fund

The ACCSION project will be one of the first full onshore Carbon Capture and Storage (CCS) value chains in Europe. This innovative project will contribute to the achievement of the 2030 Danish climate targets, but also to create a lasting positive impact on the local community. It will cover the full CO2 value chain: capture, transport, liquefaction and onshore geological storage.

ACCSION will be jointly developed by Air Liquide and Cementir. Air Liquide, through its Cryocap™, proprietary technology using a cryogenic process, will capture, purify and liquefy approximately 95% of the CO2 emitted by Aalborg plant.

Thanks to this project, Cementir would be able to avoid 1.5 million tons of CO2 emissions per year at Aalborg cement plant starting from 2030.

Captured CO2 will be transported through a newly built pipeline infrastructure and permanently stored in onshore storage facilities.

The ACCSION project would be able to significantly increase the district heating to Aalborg households.

ACCSION being one of the selected EU-funded projects

ACCSION has been selected to receive support from the EU Innovation Fund with a grant of EUR 220 million. The EU Innovation Fund, one of the world’s largest funding programs for innovative low-carbon technologies, focuses on highly innovative technologies and flagship European projects enabling significant emission reductions.

Why this project is highly innovative:

- First full onshore CCS value chain in Europe: Captured CO2 will be transported to a CO2 reception hub by pipeline and then to a suitable onshore storage.

- Capture of CO2 for both grey and white cement

- Integration with Aalborg’s district heating system: The heat generated during the capture process will be recovered to supply the city's district heating system. This smart integration is unique and builds on an established collaboration with Aalborg's municipal utilities.

- Air Liquide Cryocap™ technology

What is Cryocap™ technology?

CryocapTM is an innovative solution developed by Air Liquide for carbon capture. It leverages advanced cryogenic technology to capture CO₂ emissions by liquefying the gas under high pressure.

For more information, please visit Air Liquide website.

Disclaimer: Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.

FAQ: Understanding CCS

-

Q1: Why is CCS important for the cement industry?

A: Cement production is one of the most carbon-intensive industrial processes and is a hard-to-abate industrial process because the majority of CO2 emissions (60-65%) are produced during the manufacturing process due to the chemical conversion of limestone into calcium oxide, generating CO2 emissions as a by-product. These process emissions cannot be avoided. The role of CCS is crucial for decarbonization.

-

Q2: Is CCS safe?

A: Yes. Captured CO2 is stored in geological formations that have been thoroughly assessed for long-term stability and safety.

-

Q3: How does CCS align with Cementir sustainability goals?

A: CCS is a cornerstone of our strategy to achieve carbon neutrality by 2050, aligning with global climate targets and supporting a sustainable future for the construction sector.

-

Q4: What are the challenges of implementing CCS?

A: CCS requires substantial investments in infrastructure, energy, and technology. However, Cementir is addressing these challenges through innovation and collaboration with key stakeholders.

Additional decarbonization projects

Cementir has strategically and purposefully embarked on a dedicated journey to prepare for carbon capture projects. This initiative has included the launch of several pilot projects, providing the group with valuable experience and a deeper understanding of these innovative technologies.

CASPER Project

Purpose

The project aims to demonstrate the full CCS value chain from a cement plant. This will be done by capturing and processing at least 20 tons of CO2 from the flue gas during a campaign in 2024. Measuring the quality of the CO2 and compare with existing standards relevant in 2024. In addition, evaluating the effect of impurities on CO2 transportation in a new 50 m long CO2 pipe test facility to prepare for CO2 infrastructure that can be implemented in 2025.

| Total budget | Start and end date | Partners |

|---|---|---|

| The total budget is approximately € 2 million of which € 600,000 is funded by the project partners, including Cementir with the rest funded by the INNO-CCUS partnership funded by the Danish Innovation Fund. | 2024 to 2026. | Cementir Holding-Aalborg Portland, Technical University of Denmark-DTU, Pentair, Teknologisk Institut, Dansk Gasteknisk Center, EVIDA, Gas Storage Denmark. |

CORT Project

Purpose

The aim of the project is investigating various advanced amine solvents for carbon capture and new heat integration methods (heat pumps). Specifically, the aim is to find the best suited solvents for different carbon capture cases.

For additional information, please see https://www.cere.dtu.dk/research-and-projects/framework-research-projects/carbon-capture-open-tests-and-review-of-technologies-cort-.

| Total budget | Start and end date | Partners |

|---|---|---|

| The total funds for the project are € 2.6 million of which € 150,000 is funded by Cementir with co-funding from the INNO-CCUS partnership funded by the Danish Innovation Fund. | From 01-08-2022 to 31-07-2025. | Aalborg Portland, Pentair, Danish Technical University, Chemistry, Ørsted, Aalborg University, FORCE. |

Results

A test unit from the Danish Technical University (DTU) was established at the Aalborg Portland plant in October 2022 and it was removed in October 2023. Conclusions from gas analysis and gas purity measurements obtained and tests completed. Results for a broader audience were shared in April 2024 confiming the expectation of the Program.

ConsenCUS Project

Purpose

Show how a net-zero-carbon industry can be achieved by:

- Demonstrating the technical andeconomic viability of green electricity-based, energy-efficient CCU innovations in an industrially relevant environment.

- Investigating how CO2 networks in Northern Europe can cost-efficiently take the captured CO2 to end users, or permanent and/or intermediate storage.

For additional information, please see https://consencus.eu/

| Total budget | Start and end date | Partners |

|---|---|---|

| The total funds for the project are € 13 million of which € 240,000 is funded by Cementir and co-funded by the EU-Horizon 2020 programme. | From 01-04-2020 to 31-05-2025. | 19 partners from 7 countries. From Denmark: Aalborg Portland, DTU, GEUS and Dansk Gasteknisk Center. |

Results

On November 27th 2023, the demonstration plant was inaugurated during a short ceremony headed by the H.K.H. Kronprins and now HM King Frederik X, Ms. Simson, EU-commissioner for Energy and Mr. Aagaard, Danish Minister for Energy, Climate and Utilities. The opening event was part of the 3rd international CCUS FORUM. The CCUS FORUM is a robust stakeholder consultation platform established by the European Commission in 2021.

The test unit operated at Aalborg Portland from November 2023 to February 2024.

Public deliverables of the ConsenCUS project area available at the link https://consencus.eu/results/

Portland CC Project

Purpose

This project is part of the CO2 Vision partnership. The aim was to provide an initial techno-economic assessment of two carbon capture technologies: the amine scrubber technology (reactive absorption-stripping) and the Chart/Sustainable Energy Solutions Cryogenic Carbon Capture™ (CCC) technology applied to one kiln in the Aalborg Portland A/S cement plant. The analysis provides an estimation of component costs for the configurations under consideration using the features available in Aspen Plus®, along with electricity cost estimations for 2021 and 2022. Moreover, a suitable formulation for estimation of the cost of CO2 was presented.

| Total budget | Start and end date | Partners |

|---|---|---|

| The total funds for the project were € 503,000 of which € 131,000 was funded by Cementir. This project is supported by the EU Regional Fund and the EU Social Fund, as well as the EU Just Transition Fund. | From 01-06-2022 to 31-08-2023. | Aalborg Portland, Aalborg University, Aalborg CSP. |

Results

Both the amine scrubber technology and the Chart Cryogenic Carbon Capture™ shown to be highly effective for capturing CO2 at high purity level and capture efficiency across gaseous and liquid states. The CCC technology, in particular, distinguished itself by offering a lower energy penalty, leading to reduced OpEx, and presenting lower initial CapEx compared to the amine scrubber technology.

During the project work some future research and development activities related to capture technologies were identified as including piping and networks between the capture process and transport and storage infrastructure. It was also suggested to look at integration of capture process with other domains e.g. district heating.

For additional information see: https://www.co2vision.dk/english/

This project has been carried out as part of the activities of the public-private partnership CO2Vision. This partnership brings together local industries, educational institutions, business organisations and local government with the aim of investigating the establishment of infrastructure for CCUS in North Jutland-Denmark, including the import of CO2 for onshore and offshore storage, as well as use for production of methanol and sustainable aviation fuel.

CO2Vision partners was awarded € 12.4 million from the Danish Board of Business Development in 2022 and € 6.7 million from the EU Just Transition Fund in 2023.

The consortium partners include Aalborg University, Aalborg Portland, Labour Market Office Mid/North, Business Region North Denmark, Business House North Jutland, Energy Cluster Denmark, Evida, Green Hub Denmark, North Denmark EU Office and University College North Jutland.

GreenCEM Project

Purpose

The core objective was to identify the most promising capture technology and make a concept study of an integrated carbon capture facility at the Aalborg Portland cement plant in terms of available thermal energy, flue gas composition and site logistics leading to the lowest possible carbon capture cost.

For additional information, please see https://greencem.dk/

| Total budget | Start and end date | Partners |

|---|---|---|

| The total funds for the project were € 1.5 million, out of which € 500,000 were funded by Cementir. | From 01-08-2020 to 31-07-2022. | Aalborg Portland, Port of Aalborg, Aalborg Energi Holding, European Energy, Aalborg University, Cemtec Fonden (Hydrogen Valley), DFDS, Reno-Nord. COWI contributed as sub-contractor to Aalborg Portland. |

Results

The result of the project was a concept study for carbon capture. Two scenarios were investigated: 200,000 tons per year and 1 million tons per year captured CO2.

For additional information please see https://greencem.dk/konference/

MADE FAST Project

Purpose

Prepare a technical and economic analysis to investigate the factors (environmental, social, economic, regulatory) that could influence the carbon capture and value chains for utilisation and storage of CO2 from Aalborg Portland’s cement.

| Total budget | Start and end date | Partners |

|---|---|---|

| The total funds for the project were € 330.000 of which € 90,000 was funded by Cementir. This project was funded by the Manufacturing Academy of Denmark-MADE. | From 01-08-2020 to 31-07-2023. | Aalborg Portland, Aalborg University, Manufacturing Academy of Denmark (MADE). |

Results

The environmental analysis shows that it is possible to reach carbon neutrality when implementing CCUS if the cement facility operates with renewable energy and with a high share of alternative fuels. More details are provided in the following academic publication:

Preconditions for achieving carbon neutrality in cement production through CCUS

SNAM Polimi - CCB

Purpose

Evaluation of various capture technologies: partial Oxyfuel with Hydrogen, Partial Oxyfuel with chemical absorption using amines and chilled ammonia.

| Total budget | Start and end date | Partners |

|---|---|---|

| N/A | March to December 2022 | SNAM, Politecnico di Milano, CCB |

Results

Advantages and disadvantages of each technology were identified taking into consideration the specific conditions at the CCB cement plant. Relevant KPIs such as Capex, Opex and cost of CO2 avoidance were obtained for each solution. Further research suggests studying and concept design of an integrated project considering also CO2 transport and storage, leveraging on existing and announced projects (i. e. Fluxys) and continue with a feasibility study on the final solution.

CO2 infrastructure for Belgium

The Belgian energy infrastructure company Fluxys is designing a CO2 pipeline in Belgium, collecting the needs of various emitters and routing such CO2 to different exit points. Cementir has clearly expressed its interest in being included in such an important project, aiming at optimising the method and cost of CO2 transportation and centralising liquefaction and loading facilities.

In 2022, CCB, the Belgian subsidiary of Cementir, signed a LoI (Letter of Intent) with Fluxys.

In 2023, CCB and Fluxys further strengthened their partnership by signing an agreement to conduct a feasibility study. The study, which has now been received, is aimed at better understanding the full backbone of the CO2 pipeline network, including its technical, operational, and economic aspects.

For additional information about the CO2, infrastructure proposed by Fluxys, please refer to this link.