Concrete is part of everything surrounding us. It has accompanied urbanization and the development of societies for centuries. Durability, strength, fire resistance and acoustic insulation properties, wide availability of raw materials and low production costs have made cement and concrete among the most widespread building materials on our planet.

The development of innovative low-carbon products and the application of circular economy principles, including reuse at the end of products life cycle are some of the challenges facing the cement sector to tackle climate change.

The cement sector

Size of the cement market

In 2022, the world cement market reached around 4.1 billion tons, of which about 51% consumed in China and around 183 million in the European Union. Since 1995, when the market stood at 1.39 billion tons, the cement market has grown at a compound growth rate of 4.4% per annum, mainly driven by the rapid development of emerging countries such as China and India. On a global scale, the cement and concrete industry account for about 13% of global GDP.

Today, with around 200 active production plants in Europe, over 100 grinding plants and hundreds of concrete production plants, the cement and concrete production sectors contribute around 4.5 billion euros to direct added value in the European Union and employ over 40 thousand people.

In Europe, half of cement is used in the construction of new buildings, and 30% in infrastructure; 48% in ready-mixed concrete while around 28% in the form of precast concrete.

Key features of the cement sector

-

Commodity

Cement is a commodity and as such competition is largely on price and diversification potential is limited. In the case of white cement, however, a certain degree of diversification is possible, depending on the whiteness of the end-product, which is largely influenced by the purity of the limestone used.

-

Cyclicality

As cement is sold to economically-sensitive sectors like construction, its demand is largely influenced by GDP fluctuations. Cement consumption per capita is contingent upon the stage of development of a single economy, its urbanization and infrastructure development.

-

Capital intensity

The investment needed to build a cement plant is significant and involves complex authorization processes. Such high financial and technical barriers to entry, together with the equally high maintenance costs and technological upgrades, place the cement industry among the most capital-intensive ones. As a consequence, both investment planning and resource management span over a very long timeframe and require accurate geological, technical, market and financial assessments.

-

Energy intensity

Each ton of cement produced requires from 60 to 130 kilograms of fuel, depending on the type of cement, process and type of fuel and about 110 kWh of electricity. Technological innovation and the push towards alternative fuels has significantly reduced cement plants energy needs. Thanks to the high temperatures reached in the kiln, in many countries cement plants are used to burn waste-derived fuel (SRF/RDF), thus contributing to the development of the circular economy.

-

Transport

The high weight in relation to the commercial value of a ton of cement makes road transport over 300 km uneconomical. Hence cement is largely sold on the domestic market, (in bulk or bags) and its predominant distribution route is in the form of ready-mix concrete.

However, the use of highly efficient pneumatic vessels and the standardization of international routes have made the maritime transport of clinker / cement in bulk or container very competitive, despite the volatility of sea freight rates, paving the way for business models distributed on different geographies according to which clinker is produced in a few large plants and then transported by ship and ground locally.

In depth: cement production and the calcination process

Cement production is a continuous cycle process that involves several transformation stages. There are two main phases: a "hot cycle", which involves heating a mixture of limestone, clay and iron ore in a rotary kiln which reaches temperatures of around 1,450°C. Thanks to the calcination process, the calcium carbonate (limestone) is transformed into a reactive semi-finished product called clinker, thus releasing CO2. The other phase, called "cold cycle", involves grinding the clinker with other ingredients such as gypsum and other chemical additives, to obtain the final product. Cement is a hydraulic binder, i.e. it develops adhesive properties when mixed with water. Most of the cement is distributed in the form of concrete, a plastic material that is obtained precisely by mixing the cement with water, sand, gravel, additives and other components, in a moldable mixture that becomes "artificial rock", assuming the desired shape.

In order to produce cement, it is essential to have adequate reserves of limestone, a natural rock of sedimentary origin, widely spread in nature, consisting of calcium carbonate (CaCO3). The purer the limestone, the more the hydration process of the clinker and therefore the initial development of the mechanical strength of the cement will be accelerated.

Institutions and investors expect cement with net zero emissions by 2050

Europe has set strict targets to tackle climate change and reduce greenhouse gas emissions, with the aim of reaching the goal of decarbonisation by 2050 and all sectors with the highest carbon footprint, including steel and cement production, have made formal commitments to significantly reduce CO2 emissions. For this purpose, incentive mechanisms for CO2 reduction have been introduced, including the cap & trade emission system.

Pressure on the cement industry to decarbonise has increased rapidly, not only from society but also from investors and governments who increasingly ask for environmental impact assessments before committing resources and capital.

The Group is committed to a sustainable growth path to 2030.

The role of cement in the energy transition

Until recently it would have been unthinkable to imagine a cement production as “net-zero”. The transition to low-carbon cement by 2050 is possible but must be coordinated and planned through the collaboration of all industry players and along the entire value chain.

It is necessary to aim not only at reducing the clinker content in cement (clinker ratio) but also at increasing the use of alternative raw materials (limestone, fly ash, blast furnace slag, calcined clay) and alternative fuels, at more efficient production processes, capable of reusing combustion heat thus reducing thermal and electrical consumption.

Unlike plastics or metals, concrete is only recyclable under certain conditions and the original chemical process cannot be reversed. Nonetheless, there are opportunities to recover useful components from end-of-life cement to reduce the amount of new clinker.

The cement sector has always been traditional and conservative. Climate change, however, is imposing more radical choices, in response to the European Green Deal and the EU Taxonomy, which are contributing significantly to process and product innovation.

Our commitment

We are committed to reducing clinker content by using alternative decarbonated mineral additives, such as fly ash and slag and by developing FUTURECEM™, a new "low carbon" cement that uses an innovative process, validated and patented by Aalborg Portland, which allows about 40% clinker replacement with limestone and calcined clay, thus reducing CO2 emissions by 30% without compromising its mechanical resistance.

This is an innovation that we have put into practice for the construction of two bridges in Denmark ("Green Concrete II" project) and which has already been distributed in the Nordic markets since 2021.

-

Ready-mixed concrete: the construction material of choice

Ready-mixed concrete is the second most common element in the world after drinking water, and is used in almost everything we build, from homes to cityscapes, to infrastructure.

Characteristics of concrete

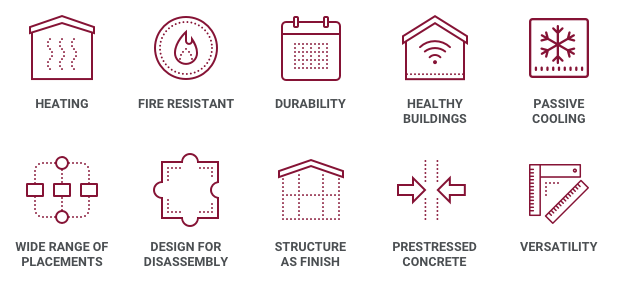

In Europe alone, concrete consumption amounts to over 1 billion tons per year, compared to 66 million tons of steel, which is the second largest widespread material in construction. The reasons for this diffusion lie in the significant benefits over other construction materials, such as: compressive strength, durability, ductility, fireproofing and insulation properties, thermal mass, carbon absorption, wide availability of raw materials and production cost.

Why concrete?

For these reasons, concrete is the material shaping the world around us and can continue to play an important role in responding to the key challenges of the near future: sustainable growth, building safe and accessible homes, responding to population and urbanization growth. Concrete allows the construction of infrastructure that our communities will increasingly need.

Modern society expects construction - buildings, bridges and other infrastructure - to be durable and safe. There is also an expectation of resilience in the face of possible extreme climatic events or catastrophic events such as fires, which other materials, such as wood, cannot guarantee. The ability to withstand extreme events and not to catch fire makes concrete a unique building material in terms of safety.

Overall, when considering the performance of a building during its entire life cycle, the properties of concrete make it an irreplaceable material to mitigate climate change and develop sustainable construction.

-

Ready-mixed concrete recarbonation

Ready-mixed concrete absorbs CO2 throughout its life cycle, a process known as cement recarbonation or carbon absorption.

Recarbonation is a natural process, which occurs when concrete reacts with CO2 in the air. The actual amount of carbon absorption depends on a number of parameters including the strength class, the exposure conditions, the thickness of the concrete element, the recycling scenario and secondary use. Studies showed that 25% of the process CO2 emissions released during cement production are reabsorbed.

Another significant part of the carbon uptake of concrete occurs when reinforced concrete structures are demolished, as increased surface area and exposure to air accelerate the recarbonation process. The amount of carbon uptake is even greater when the crushed concrete stocks are left exposed to air before its reuse.

-

Circular economy: concrete recycling

The use of recycled concrete for aggregates is a clear and obvious example of a circular economy and has the advantage of reducing the use of natural resources and landfilling.

Recycled concrete is mainly used for road construction, with smaller quantities also used in the production of new concrete, the quality of which can be maintained at the levels of a virgin concrete by optimizing the mix of ingredients.

Recycling rates for crushed concrete vary significantly depending on local laws and regulations for landfilling of demolition waste and access to natural aggregates. Where there are incentives and / or penalties, the aggregates industry has adapted to increase the use of recycled concrete as a source of aggregates. Policies requiring the segregation of good quality concrete waste during demolition processes, in addition to maintaining its traceability, also help to maximize the reuse of recycled concrete aggregates. High recycling rates are reported in the Netherlands, the UK and Japan.

-

The involvement of the whole value chain

Moving to a net zero-carbon system is a considerable challenge and will require changes throughout the value chain and significant investments.

Sustainability can be the catalyst that drives the industry to seek growth through new business models, partnerships and innovative approaches. Concrete will remain the building material of choice globally, but “sustainable building” value chains are likely to emerge at the regional and local levels, requiring a reorientation of many processes and business models.

The cement industry is predominantly a local business; therefore, we need to keep a market-by-market perspective in order to seize transversal opportunities and achieve better results.