"The fact of being able to create melted stones of any shape, superior to natural, because capable of resisting to tensions, has in itself something magical".

Concrete is the most common construction material on our planet thanks to its mechanical performance, high flexibility in use and its durability over time.

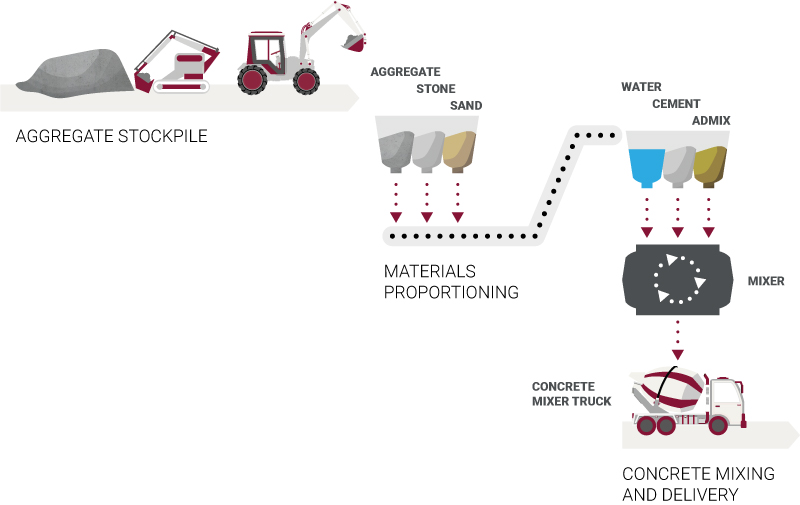

Concrete is a plastic material that is obtained by mixing sand, gravel, additives and other components with a hydraulic binder like cement. The addition of water transforms this mixture into "artificial rock" thanks to a process called hydration that binds all the components together.

At the time of preparation, concrete is an easily workable plastic mass with which to make a wide variety of shapes for different applications such as plinths, foundations, pillars, beams, walls and roofs.

Concrete is a product that is generally pre-packaged inside the concrete mixing plants where the mixture is accurately dosed and then transported to the construction site with truck mixers able to ensure continuous product mixing and to maintain the fluidity characteristics essential for its end-use.

Once the concrete delivered to the construction site, it is ready for the so-called casting. In order to reach certain heights necessary for the construction of high rise buildings, concrete is pumped upwards through pipes.

Whilst the most common mechanical property of concrete is compressive strength, other characteristics may become relevant based on end-use, such as resistance to thermal variations or to alkalis and sulphates. The considerable diffusion of concrete over the years is due to reinforced concrete, where the use of steel bars reinforcement increases its tensile strength and allows the construction of complex structures.

The Aalborg Portland Holding Group has developed an innovative range of solutions covering all classes of concrete in compliance with the best international standards. Thanks to our fixed and mobile systems, a variety of concrete pumps, geolocation software and over 2,000 special mixtures, we are able to support the construction of any project and meet the main challenges of our customers: greater environmental sustainability, building energy efficiency, cost reduction, construction speed and site productivity, as well as improving buildings architectural and aesthetic qualities.

We produce coloured concrete by adding pigments to the mixture made with AALBORG WHITE®. We are also at the forefront in the study of low environmental impact concretes such as "Green Concrete" which allows greater environmental sustainability of this universal product.

- Infrastructure

- Landscaping

- Industry and agriculture

- Energy and environment

- Buildings (residential and commercial)

- Pre-stressed and prefabricated concrete products

Precast concrete products

The Group produces prestressed concrete products in the Vianini Pipe Inc. plant in the United States. These products are structural components for building and transport (pipelines, jack pipes, box culverts, blocks, tiles, railway sleepers, etc.) obtained through the use of mechanical and hydraulic technologies which use concrete as raw material.

We offer a wide range of products: grey cement, white cement, aggregates, concrete, value-added products, trading.

We have executed projects all over the world, supporting our customers in all stages of implementation by using cutting-edge technologies.

We are a Group with a truly international mentality. We have registered offices in Denmark and operations in 18 countries.